How to Effectively Use a Used Scissor Lift for Your Next Project

When planning your next construction or maintenance project, one tool that can significantly enhance efficiency and safety is a Used Scissor Lift. According to industry expert, John Matthews, a seasoned equipment rental manager, "A properly utilized used scissor lift can dramatically improve access to hard-to-reach areas, ultimately saving time and reducing labor costs." This statement underscores the importance of understanding how to effectively integrate such equipment into your workflow.

Used scissor lifts offer a cost-effective solution for many projects, providing the necessary height without the burden of new equipment expenses. However, to maximize their potential, operators must be well-informed about safety protocols, maintenance checks, and the specific requirements of their tasks. By leveraging the insights of industry professionals and investing time in proper training, project managers can ensure seamless operations and enhanced productivity with a used scissor lift.

As you delve into the nuances of utilizing a used scissor lift, it is crucial to recognize both the advantages and responsibilities that come with such equipment. Whether you're working on a small renovation or a larger construction endeavor, understanding the best practices associated with a used scissor lift will not only improve project outcomes but also pave the way for safer work environments.

Choosing the Right Used Scissor Lift for Your Project Needs

When choosing the right used scissor lift for your project needs, it’s essential to assess the specific requirements of the tasks you plan to undertake. First, take into consideration the height you need to reach. Different scissor lifts offer varying maximum working heights, so ensuring that the lift can safely accommodate your project is crucial. Additionally, analyze the weight capacity of the lift, especially if you will be lifting heavy materials or multiple workers simultaneously.

Another important factor to consider is the lift’s surface compatibility. Some projects may be conducted on uneven terrain, requiring a machine designed for stability on such surfaces. In contrast, if your project is indoors or on a flat surface, a standard scissor lift would suffice. Furthermore, pay attention to the lift's power source—electric lifts are ideal for indoor use, while diesel-powered models may be more appropriate for outdoor projects. By focusing on these specifics, you can select a used scissor lift that will enhance the efficiency and safety of your project.

Inspecting a Used Scissor Lift Before Purchase

When considering a used scissor lift for your next project, conducting a thorough inspection before purchase is crucial to ensure safety and reliability. Start by examining the overall condition of the lift, including its structural integrity. Look for signs of physical damage such as bent frames or rust, as these can indicate underlying problems that may affect the performance of the unit.

Next, check the operating mechanisms, including the hydraulic system, to ensure they function smoothly. Test the lift to confirm that it ascends and descends without hesitations or irregularities. Additionally, inspect the safety features such as emergency controls and guardrails. These components are vital for the safe operation of the lift, and any deficiencies should raise red flags. Lastly, review the maintenance history if available, as a well-documented service record can provide insights into the lift's reliability and any past issues that have been addressed.

How to Effectively Use a Used Scissor Lift for Your Next Project - Inspecting a Used Scissor Lift Before Purchase

| Inspection Criteria | Recommended Action | Importance Level | Notes |

|---|---|---|---|

| Overall Condition | Check for signs of wear or damage. | High | Look for rust, dents, or any structural issues. |

| Hydraulic System | Test for leaks and responsiveness. | Critical | Ensure smooth lifting and lowering operations. |

| Electrical Components | Inspect battery health and wiring. | High | Check for corrosion and ensure connections are secure. |

| Safety Features | Verify functionality of guards and emergency brakes. | Critical | Safety should be a top priority during inspection. |

| Tires and Wheels | Check for tread wear and air pressure. | Medium | Ensure stability during operation. |

| Manual and Documentation | Request for available manuals and service history. | Medium | Helps understand service intervals and maintenance records. |

Best Practices for Operating a Used Scissor Lift Safely

Operating a used scissor lift requires a clear understanding of safety measures to prevent accidents and ensure the well-being of workers. According to the Occupational Safety and Health Administration (OSHA), falls are among the leading causes of workplace injuries, making it imperative to adhere to guidelines for using scissor lifts. Before commencing work, operators should conduct a thorough pre-operation inspection, checking critical components such as the lift's brakes, controls, and safety features. A recent report by the American National Standards Institute (ANSI) highlights that regular maintenance and inspections can reduce the likelihood of equipment failure by over 30%, emphasizing the importance of these practices.

Training is another crucial aspect of operating a scissor lift safely. The ANSI standard mandates that operators must be well-versed in the specific equipment they are using. This means participating in training sessions that cover operational procedures, hazard awareness, and emergency response strategies. A study by the National Institute for Occupational Safety and Health (NIOSH) reported that properly trained operators are less likely to experience accidents, reflecting a 25% reduction in incidents compared to untrained personnel. Therefore, investing in training not only promotes a safer workplace but also enhances productivity by ensuring that employees are confident and competent in using the equipment.

Usage Trends and Safety Practices for Used Scissor Lifts

Maintenance Tips to Extend the Life of Your Scissor Lift

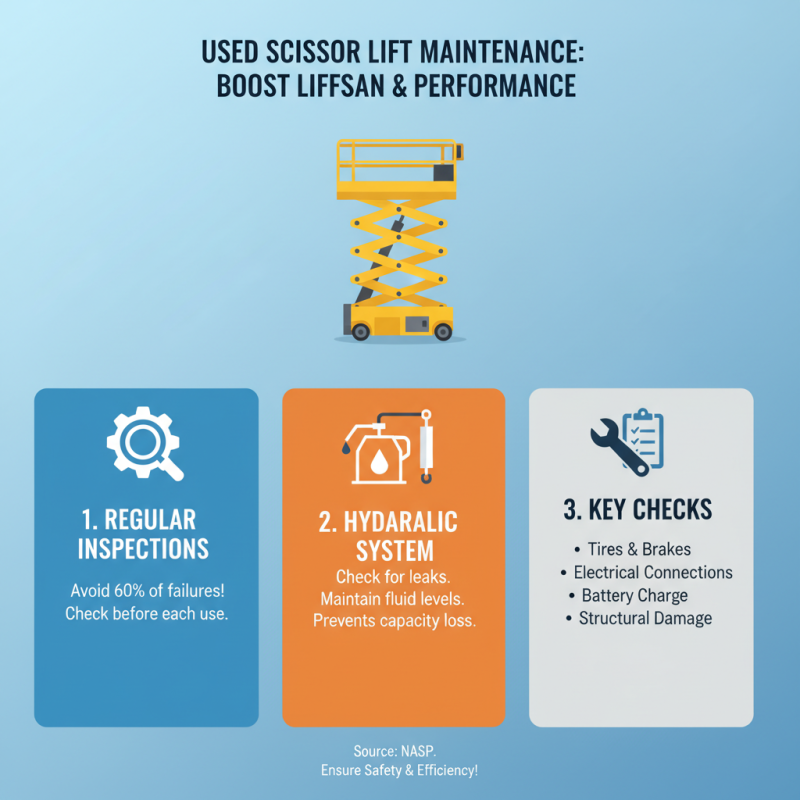

Maintaining a used scissor lift is crucial for maximizing its lifespan and ensuring optimal performance on your projects. Regular inspections are key; according to the National Association of Safety Professionals, up to 60% of equipment failures can be avoided with proper maintenance. Begin with a thorough check of the hydraulic system, as leaks can lead to significant operational issues. Look out for fluid levels, ensuring they are within the recommended range, as low levels can diminish lift capacity and efficiency.

Additionally, keeping the lift clean is vital. Debris accumulation can cause mechanical parts to wear down prematurely. The Occupational Safety and Health Administration (OSHA) recommends that operators perform routine cleaning of the equipment, focusing on the lift mechanics and platform. Moreover, inspect the electrical systems for any signs of wear or corrosion. Data from the Equipment Leasing and Rental Association indicates that equipment properly maintained has a higher resale value, with estimates suggesting a difference of up to 20% compared to poorly maintained lifts. Emphasizing these maintenance practices will not only extend the life of your scissor lift but also enhance safety and productivity during operation.

Transporting and Storing Your Used Scissor Lift Properly

When it comes to transporting and storing your used scissor lift, proper procedures are essential to ensure safety and longevity. Before moving the lift, make sure it is fully lowered, the emergency stop is engaged, and all attachments are removed. To protect the lift during transport, use appropriate straps and padding to prevent movement and potential damage. If you're using a trailer, secure the lift with wheel chocks to avoid any rolling during transit. It's also wise to check the weight limit of your transport vehicle to ensure it can handle the load safely.

Once you've reached your destination, the way you store your scissor lift is equally important. Choose a dry and secure location to prevent exposure to harsh weather conditions which can lead to premature wear or rust. Position the lift on a flat, stable surface to minimize the risk of tipping. If possible, cover the lift with a protective tarp to shield it from dust and debris. Additionally, conducting regular inspections for any signs of damage or wear during storage can help you maintain the equipment in optimal condition for your next project.

Related Posts

-

Unlocking Efficiency: The Benefits of Quality Forklift Parts for Your Business

-

Comprehensive Guide to Best Electric Pallet Jack Specifications and Operational Tips

-

Essential Guide to Reach Trucks: Maximizing Warehouse Efficiency with Data-Driven Insights

-

Embracing Innovation in 2025 How to Choose the Best Pallet Lifter for Your Supply Chain

-

What Makes the Best Powered Pallet Jack Stand Out in Material Handling

-

The Ultimate Guide to Choosing the Right Electric Pallet Jack for Your Business Needs